Proper lubrication of roller chains is a very important factor in getting their best possible performance and longest life. No matter how well a transmission system is designed, if it is not properly lubricated, its service life will be shortened. Abrasion between the pin and bushing causes the roller chain to elongate. Therefore all parts should be well lubricated. The gap between the pin-link plate and roller-link plate on the slack side of the chain should be filled with lubricant. The oil forms a film which minimizes wear of the pin and bushing thus increasing the chain service life. It also reduces noise and acts as a coolant on high speed applications.

SUGGESTED LUBRICANTS

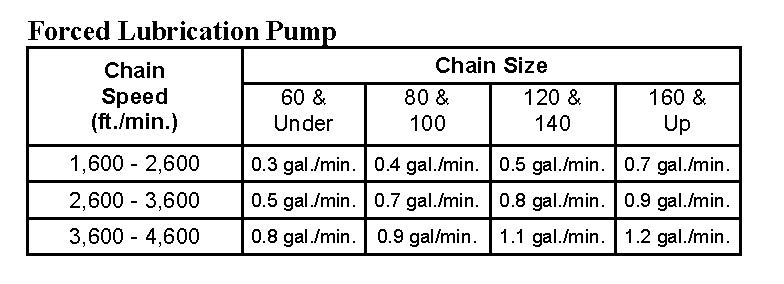

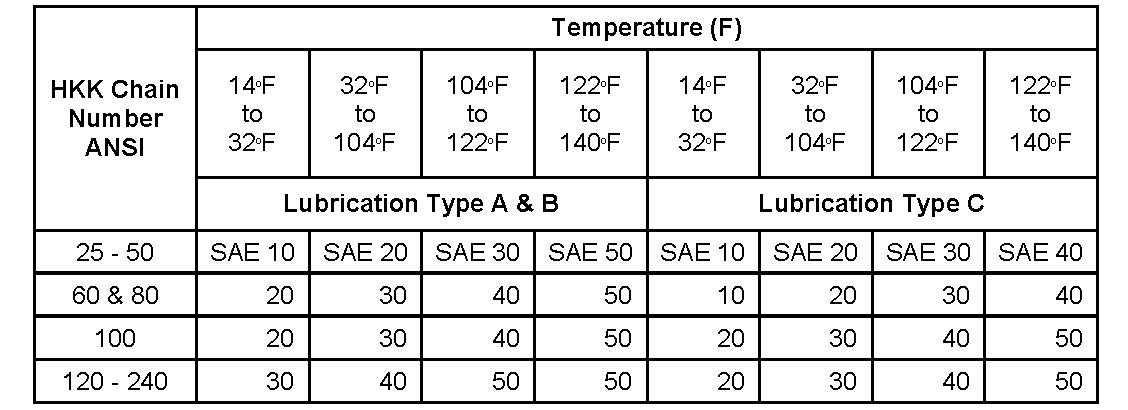

Neither heavy oil nor grease is a suitable roller chain lubricant. Only high quality oil should be used. Viscosity of the oil used will depend on the chain size, running speed and ambient temperature. Recommended viscosity for temperature and size of chain can be found in the table below.

Regardless of the application and method of lubrication, the chain should be periodically cleaned with a petroleum cleaner and inspected. Damage and/or reddish brown discoloration on the pins and/or bushings indicate inadequate lubrication.

Type | Method | Amount | |

|---|---|---|---|

A |  |

| |

|

| ||

|

| ||

B |  |

| |

C |  |

|