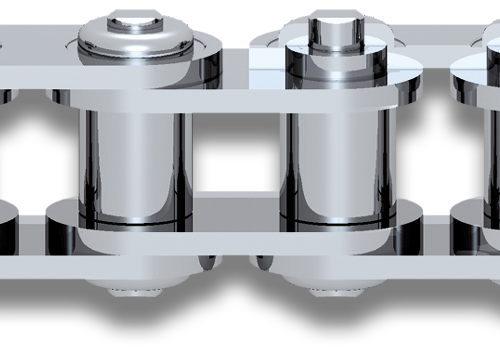

A Pioneer in the Industrial Chain Business

Manufacturing the highest quality industrial roller chains,

engineering class chains, and environmental products.

MAXCO CHAIN NEWS

Industry Members